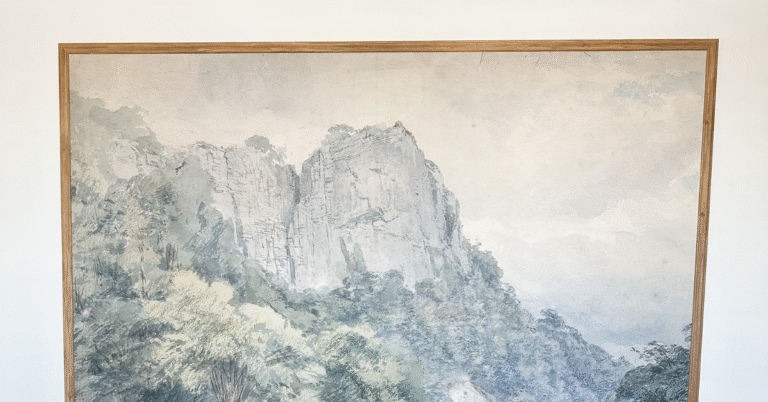

Custom Bench: The Ultimate Statement Piece for Your Home

I found this bench that loved. However, I did not love the $1,000 price tag! Lucky for me, I can make my own bench for a fraction of the price. Follow along with this tutorial and you can make a custom bench of your own! Also, if you missed my grid wall I did, you can check out how to do that yourself HERE! I love the way it looks.

Custom Bench Supplies:

- 2×2

- 1×2

- Cane Webbing

- Pocket hole screws

- Foam

- Fabric

Tools for Custom Bench:

- Staple gun

- Pocket hole jig

- Sewing machine

- Table Saw

In order to make this bench look the best, you will need a pocket hole jig. You can get away without a table saw, if you can get 1×1 dowels.

Custom Bench Step 1: Make cuts

First thing you will need to do is cut your wood.

2×2:

- 4- 26.5 inches

- 2- 15 inches

Cut the bottom 4 inches at an angle, to create a stylized leg.

Repeat on both sides of the 12 inch pieces to form a V

1×2:

- 4- 18 inches

- 3- 56 inches

- 1- 11 inches

1×1: You may need to rip a 1×2 down on a table saw.

- 8- 8 inches

- 4- 16 inches

- 4- 25 inches

Scrap wood:

- 5- 18 inches (can be any width between 2-5 inches wide)

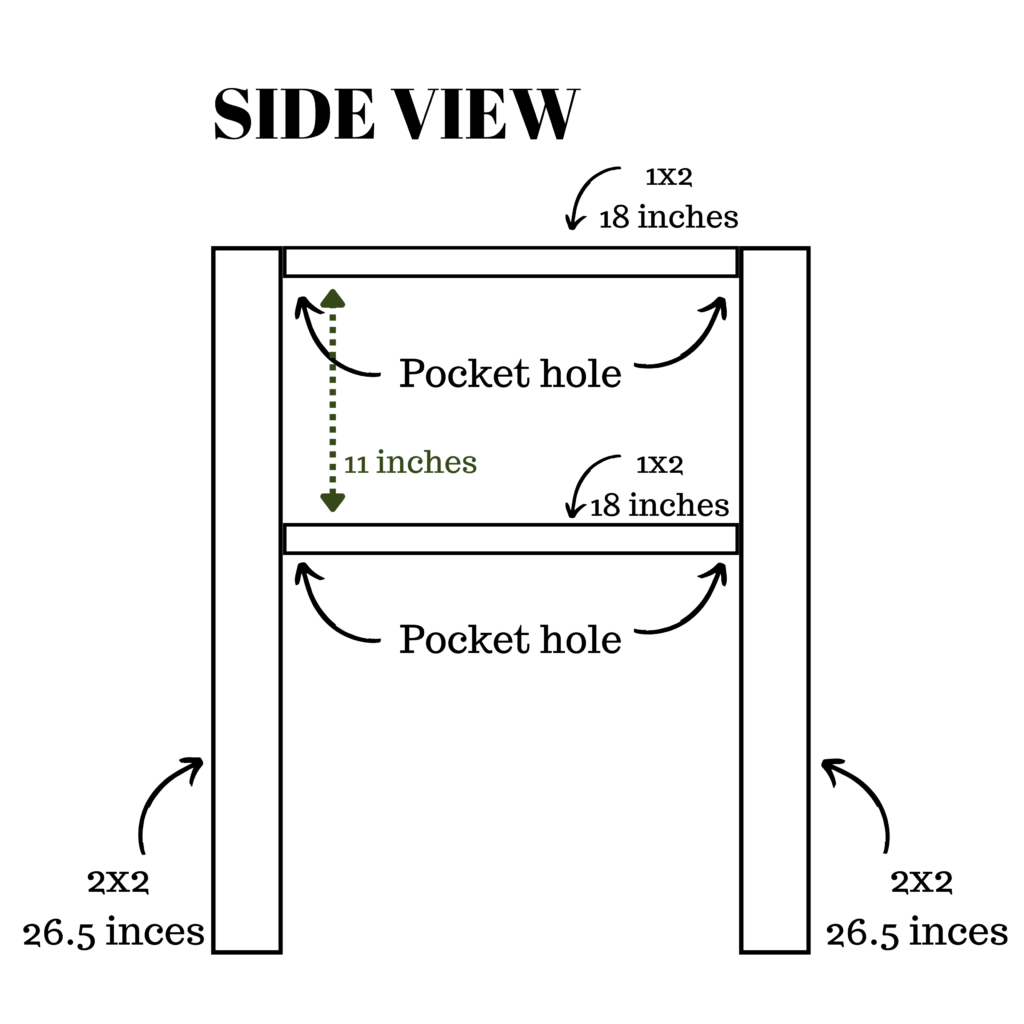

Step 2: Sides

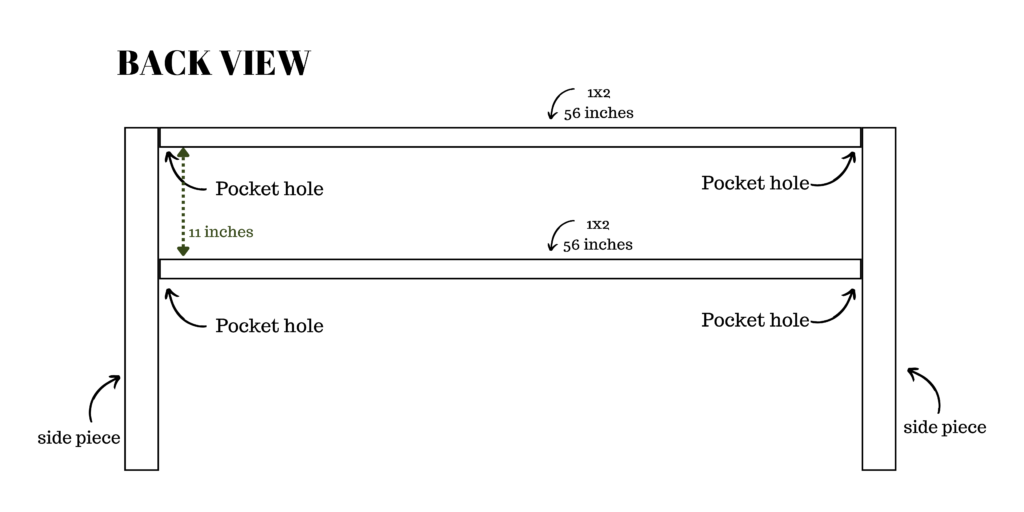

Take 2 of the 26.5-inch 2×2 and 2 of the 18-inch 1×2. Put a pocket hole on the bottom of each side of both of the 1×2.

Secure one 1×2 to the top of the 2×2’s. Make sure the angle piece of the 2×2 is at the bottom facing away from the 1×2.

Next, secure the second 18-inch 1×2 11 inches down from the top 1×2.

Repeat for the other side.

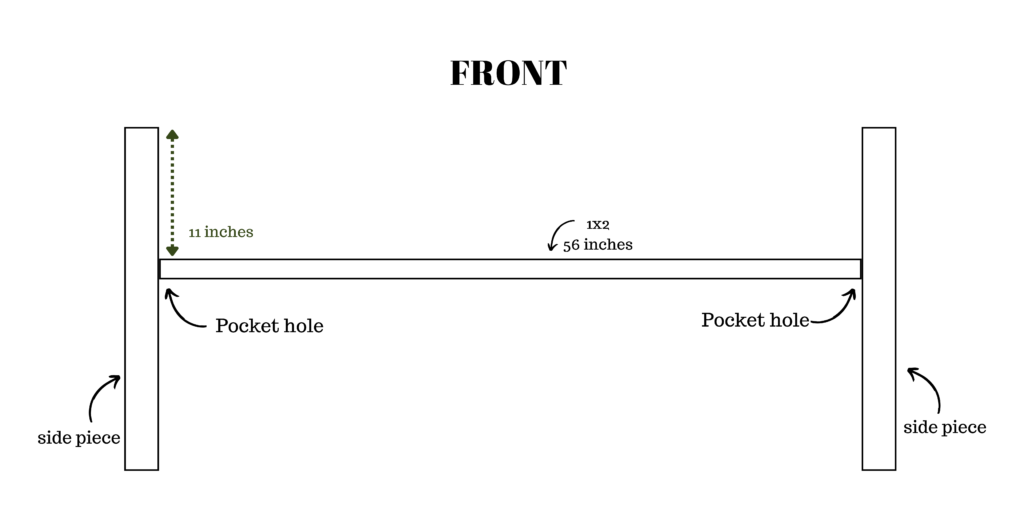

Step 3: Front, back and seat

Drill pocket holes in the bottom of each side of the 56-inch 1×2’s. Then secure one at the top of the 2×2, one 11 inches down to be in line with the 1×2 on the side, and one on the front side of the side pieces 10 inches down.

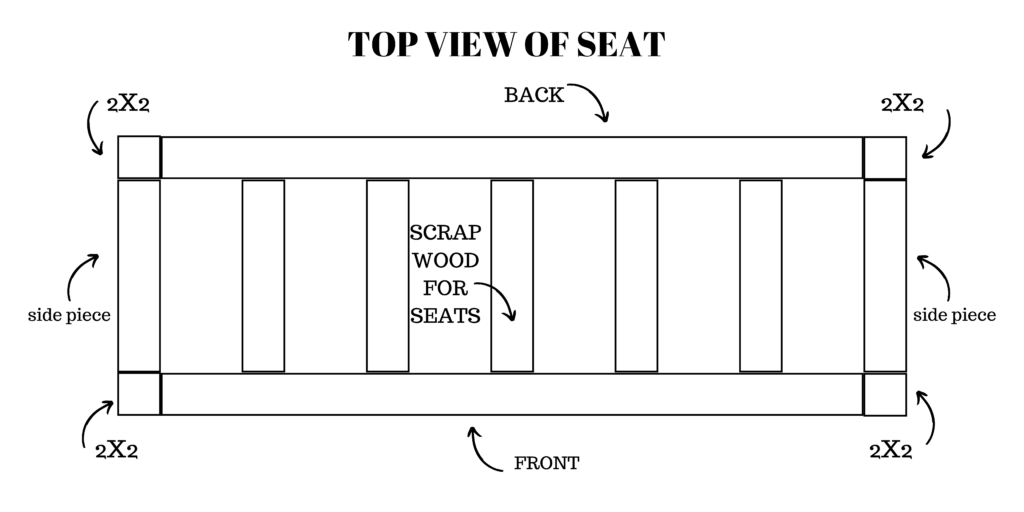

Finally take your scrap wood that you cut to 18 inches and put 2 pocket holes on each end of it. Install it between the front and back middle pieces of 1×2.

Step 4: Support Legs

Take your remaining 2 15-inch 2×2 and put a pocket hole in the back sides. Secure them into the middle of the 56-inch 1×2 to create center support legs.

Your frame is now complete! Yay!

Step 5: Finish work.

The great thing about pocket holes, is they are in a spot that you cannot see so you do not have a bunch of holes you need to fill. However, if you would like to seal up the pocket holes. You can. Get THESE pocket hole plugs and hammer them into the holes. You can then use wood filler and sand them flush. They make the holes disappear.

Give the frame a good sanding to make everything smooth and splinter free. If you want to stain it or paint it, now is the time to do that!

Step 6: Cane Webbing Frames

We will be creating “frames” that we will staple the cane to. So carefully measure and cut so the frames fit snug.

I used my table saw and ripped down my 1×2 to be a 1×1. Take 2 of the 16-inch 1×1 and put a pocket hole in each end. Attach the 8-inch 1×1’s to the 16-inch 1×1’s to create a frame.

Repeat for the second 8×16 inch frame and again for the 2 other 8×25 inch frames.

Dry fit the frames to make sure they fit with a little space for the cane to go.

Step 7: Time for the cane!

When working with cane, it is recommended that you soak it for 30 minutes. The cane will soften up making it much easier to work with.

Stretch it over the frame and staple it to the SIDE of the frame. Make sure you pull it tight. As it dries it will tighten up a little more and will be strong.

Put the frames in the spaces and use a nail cut to secure them in place.

Step 8: Cushion

I am not a seamstress, but I can sew a straight line! So, if you can sew a straight line, you can do this too. Keep in mind, these measurements are giving you a ½” room for overhang on the fabric.

Start with cutting your fabric. You will need 2 pieces 53×19”, 2 pieces that are 5×19 and 2 that are 53×5”.

Start by sewing the 5” pieces together to make one long 141” piece. Remember when sewing a case, always sew the fabric right side together. You will then turn in it right side out once you are complete.

Then take one of the 53×19 inch pieces and sew it to one end of the 141” piece all the way around. Repeat with the second 53×19 inch piece leaving one end open.

Insert the foam into the case and then either manually sew it closed, or you can attempt to close it with the sewing machine.

Put your cushion on the bench and you are complete!

What do you think?! Do you love it? Doesn’t it feel so good to create something so beautiful with your own 2 hands! To get quality furniture for a fraction of the cost to buy it retail? I would love to see your finished product.

Follow along for more DIY’s and fun at…